Posted 27 November 2019

Steel Wire Armoured Power Cables

Whilst the weight and rigidity of armoured cables can make them hard to handle and time-consuming to terminate, they are essential in applications where unarmoured cables may be prone to damage and require containment protection, i.e.: conduit or trunking.

Where should you use armoured cables?

Armoured cables are the ideal solution for any electric circuit that may be subject to physical damage. In this context, armoured cables are most often used for fixed power installations in industrial applications, such as power distribution in a plantroom, where cables may be damaged by maintenance operations, for example.

Clause 522.8.10 in BS7671 requires that cables buried in the ground shall incorporate an earthed armour. When the ground is opened again for maintenance, an unarmoured cable might be hit by excavation plant or even a spade, and damaged, and without any earthed protection, could lead to an electric shock.

Are there different types of armour?

Single core power cables for AC voltages will incorporate a layer of protective aluminium armour (AWA). This is because a magnetic field is produced by the current in a single core cable which induces an electric current in any ferromagnetic armour material, such as steel, which could lead to the cable overheating. If this were to happen, the 'magnetic losses' would be prohibitive and massively de-rate the cable. The cores will also physically repel each other. (You can read more about this in section 521.5.2 of the 18th edition of the Wiring Regulations, BS 7671:2018.)

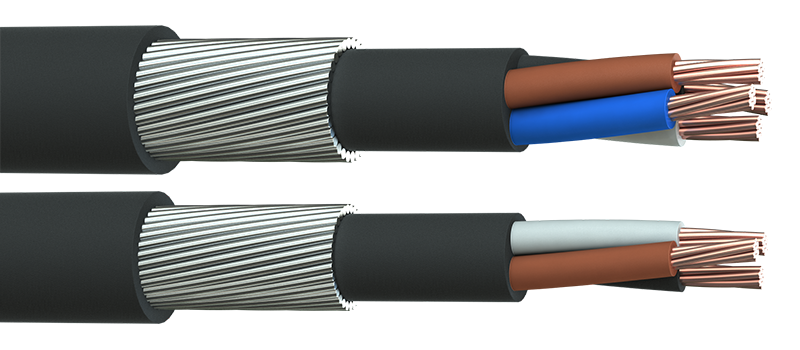

For multicore cables, galvanized steel wire armour (SWA) is used. Magnetic fields are not an issue in multicore cables as the currents in a cable with two or more cores will exert opposite magnetic forces which have a cancelling effect on each other, so that no magnetic flux is produced in the cable’s steel armour.

XLPE insulated, PVC sheathed SWA and AWA cables are manufactured in accordance with BS5467. Typically, SWA cables are constructed with class 2 stranded plain annealed copper wire conductors to comply with BS EN 60228. These are covered by an extruded layer of cross-linked polyethylene insulation. The insulated conductors are then ‘laid-up’ or helically wrapped together and a bedding layer extruded on top. The whole assembly is then enclosed in a layer of armour to provide mechanical protection. A PVC outer sheath provides additional protection from sunlight and water.

LSHF Cable is manufactured to BS 6724. This cable can be used as a direct replacement for PVC sheathed standard BS 5467 armoured cables for applications where low smoke, zero halogen performance and improved flame propagation is required.

Fire resistant (circuit integrity) versions are also available to BS 7864. Prysmian lead the market with their FP400 & FP600S cables which feature conductors wrapped in mica-glass fire resistant tape in addition to XLPE insulation to maintain circuit integrity and/or operation during a fire.

Terminating an armoured cable

Armoured cables can be particularly tricky to terminate. It is time consuming operation to strip back the different layer as well as the armour. Specialist tools can help speed the process, but otherwise it’s necessary to remove the cable sheath and cut through every single armour wire encasing the cable.

Once the armoured layer has been removed, the bedding layer is carefully cut back so as not do damage the cable cores, and the insulation can be stripped from the cable cores to allow the cable to be terminated.

It’s important to terminate an armoured cable with a metal gland that anchors the armour. BW-type glands are used for indoor applications as they simply anchor the armour, there is no protection against moisture or dust. CW-type glands are suitable for outdoor applications due the additional seal onto the outer jacket providing weather protection. Particular care needs to be exercised when specifying glands for use on cables in hazardous areas, these types are known as EX glands. Finally, it’s also important to earth a metallic gland as this will earth the armour to make the circuit safe.

BS 5467 & BS 6724 cables will be CPR compliant however the Euroclass may vary from one manufacturer to another. Most commonly BS 5467 is class Eca although there are some Dca products in the market. BS 6724 can range from Eca to B2ca depending on the size and manufacturer.